Chemical reactors for catalytic processes

- Four commercial automated lab reactors MicroActivity model (PiD Eng&Tech) which operate with flows in the range from tens of ml/min to L/min, pressures ranging 1 to 100 bar, and reaction temperature ranges from room temperature to 1000 °C (using special material reactors – HASTELLOY C276 or SS-316).

- Three homemade reaction systems specifically designed to perform different catalytic reactions such as methanation, WGS/rWGS or reforming of tars.

- Commercial Pilot Plant designed by PiD Eng&Tech for coupling a reforming reaction with a cleaning-up process in microchannel reactors

- Two commercial stirred tank reactors from PARR for higher operating pressures (up to 345 bar) and temperaturas up to 350 °C.

- One commercial chemical synthesis reactor from METTLER TOLEDO to achieve a precise control and maintains reaction temperature ensuring a reproducible process.

- One homemade lab system for bath reactions.

- Reactor for pyrolisis treatments and biochars production

- Multiple paralel bath reactors (High-troughput)

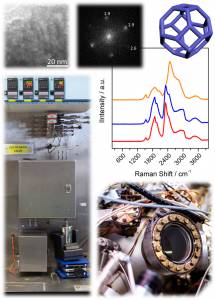

Materials Characterization

- X-ray diffraction (Philips X´PERT PRO equipped with high-temperature chamber up to 1200 ºC)

- Reflectometry and small angle X-ray spectroscopy (SAXS) for analyzing solid surfaces

- Raman spectroscopy (LabRAM Horiba Jobin Yvon with 3 excitation energies at 325 cm-1, 532 cm-1, and 785 cm-1)

- UV-Vis-NIR spectrophotometer which operates in transmission mode or in diffuse reflectance.

- Infrared spectrometer (JASCO FT/IR-6200 IRT-5000) with diverses accessories to operate in diffuse reflectance (DRIFT), attenuated total reflectance (ATR) or fixed-angle specular reflectance mode

- Physisorption analysis (TRISTAR II/TRISTAR II-Kr from Micromeritics equipped with automated three-station for surface area and porosity analysis)

- X-ray photoelectron spectroscopy (XPS) for surface chemical analysis (Leybold – HerAeus LHS 10/20 model). High pressure and high temperature chamber for pretreatments.

- High-resolution transmission electron microscopy (HRTEM) FEI TALOS S200S model equipped with a STEM detector in three operation modes (BF, ADF and HAADF), a CCD camera Ceta16M and an EDX analyzer for compositional analysis.

- Scanning electron microscopy (SEM) HITACHI S4800 SEM-FEG equipped with a Bruker-X Flash-4010 EDX detector.

- Pulse chemisorption measurements and temperature-programmed experiments (TPR, TPO, TPD, TPSR) with TCD detector and mass-spectrometer (MS) coupled.

- Inductively coupled plasma atomic emission spectroscopy (ICP-AES) for chemical analysis.

In situ/operando techniques

- Two quartz cells for in situ FTIR studies of probe molecules adsorption (CO, CO2, NH3, Pyr, etc.)

- DRIFTS cell for operando studies under reaction conditions (900 ºC and 20 bar)

- Sandwich cell for operando studies in transmission mode (400 ºC and 4 bar)

- Linkam cell for catalytic studies in operando conditions by Raman spectroscopy

- Linkam-adapted cell with fiber-optic coupled for UV-Vis operando measurements

- Homemade FTIR gas cell for analysis under flow conditions

- In situ DRIFTS cell specially designed for simultaneous infrared and conductance analysis of sensors.

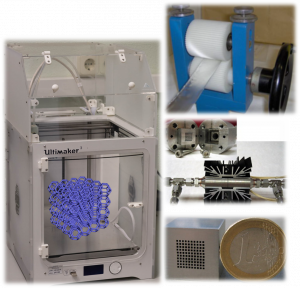

Design & Manufacture of microreactors

- 3D-Printer for additive manufacturing of flow devices, monoliths and microreactors.

- Mechanical workshop for fabrication of a wide range of devices (teflon, aluminum or stainless Steel) and welding processes.

- Preparation of slurries and rheological properties (viscometer, pH meter, isoelectric point and particle size).

- Manufacture of metallic substrates.

- Washcoating methods.

Cromatography methods

- Three microGC equipped with two modules and two TCD detector

- Two GC equipped with three modules and TCD/FID detectors.

- High Performance Liquid Cromatography with refraction index detector

- High Performance Liquid Cromatography with automatic sampling (refraction index and UV detector)